SFPOC ADSS provides high optical fiber count communication system on overhead power lines.It is custom designed to satisfy each customer's specified communication requirements of diameter,fiber count,fiber characteristics, tensile strength etc. in compliance with IEEE and IEC International Standards.

SFPOC ADSS cables are light in weight and small in diameter and hence help in reducing the load on structures due to cable load, wind load and ice load. The ADSS cable can be installed under the phase wires even in live line conditions. Installation of ADSS cable is simple utilizing standard hardware and equipment for fiber optic cables.

SFPOC provides with its products a comprehensive range of services,including hardware, installation supervision, type testing and training.

ADSS Cable Design Features

All Dielectric Self-Supporting, (ADss) Cable is one of the most efficient overhead fiber optic communication systems and high-performance aerial applications installed on power transmission and distribution lines,As the name of the cable indicates, it is an all-dielectric cable with no metallic component and as a result can be used in strong electrical environments without any concern of electromagnetic interference on fiber optic communication. This helps in eliminating additional costs for cable grounding.

ADSS cables are installed on power lines and are often subject to various types of environmental conditions including heavy ice and wind. It is therefore essential for the ADsS cable to have adequate strength to withstand mechanical stres and strain especially when installed on long spans. With no metallic component, ADSS cable Is designed to have sufficient strength to support itself when installed on power transmission or distribution lines. ADsS cable with single or double jackets and high strength aramid yarns can be designed to be used on very long span.

ADSS cable can be designed to accommodate high fiber count. The optical fibers are placed loose in gel filled color coded PBT tubes with certain excess fiber length to avoid any stress or strain on the fibers due to elongation under high tension. Water blocking tapes are used around the tubes to prevent any damage to fibers due to water/moisture ingress. The PBT tubes are stranded around a central strength rod of FRP. Adequate number of aramid yarns are placed in between inner sheath and outer sheath for necessary strength.

ADSS cable can be designed with tracking resistant jacket to protect from Dry Band Arc damage and make it suitable for use in high voltage power lines.The optical fibers used in ADsS are of premium quality conforming to ITU standards.

The optical fibers have low signal attenuation and wide band width allowing for long distance, high-capacity communication.

All Dielectric Self Supporting (ADSS) Cable

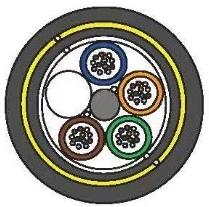

| Cross Section Drawing of 48 Fibers ADSS |

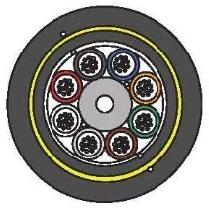

Cross Section Drawing of 96 Fibers ADSS |

Cross Section Drawing of 144 Fibers ADSS |

|||

|

|

|

|||

| NESC Heavy @1%Installation Sag | |||||

| Span 1000ft | |||||

| Diameter | |||||

| Inches | mm | Inches | mm | Inches | mm |

| 0.539 | 13.7 | 0.681 | 17.3 | 0.847 | 21.5 |

| Weight | |||||

| Lb/Ft | Kg/Km | Lb/Ft | Kg/Km | Lb/Ft | Kg/Km |

| 0.094 | 140 | 0.151 | 224 | 0.233 | 346 |

| Maximum Rated Cable Load (MRCL) | |||||

| Lbf | KN | Lbf | KN | Lbf | KN |

| 3393 | 15.1 | 3815 | 17.0 | 4907 | 21.8 |

Typical Fiber Types and Optical Characteristics

| Fiber Type | ITU-T-G652D Fibers | ITU-T-G655 Fibers | Low Loss Fibers | Ultra-Low Loss Fibers |

| Attenuation @1310nm |

0.35 | 0.35 | 0.34 | 0.32 |

| Attenuation @1550nm |

0.22 | 0.22 | 0.19 | 0.18 |

Keywords

SFPOC-ADSS

Contact Us

Classification: